How Does a Copper Compression T Fitting Perform in Modern Plumbing Systems?

2025-12-18Abstract

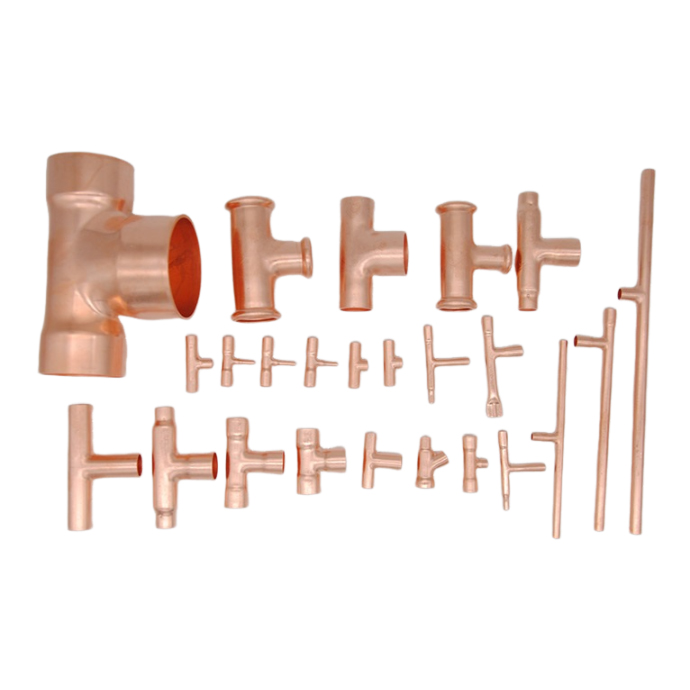

Copper Compression T Fittings are widely adopted in plumbing, HVAC, and fluid distribution systems where reliability, ease of installation, and long-term sealing performance are critical. This article provides a comprehensive professional analysis of how Copper Compression T Fittings function, what technical parameters define product quality, and how they respond to evolving installation standards and system requirements. Through structured technical explanations, application-based reasoning, and practical FAQs, this guide clarifies why this fitting type remains a core component in copper piping networks worldwide.

Table of Contents

- 1. How Does a Copper Compression T Fitting Work?

- 2. How Are Product Parameters Defined for Copper Compression T Fittings?

- 3. How Is a Copper Compression T Fitting Applied Across Industries?

- 4. How Will Copper Compression T Fittings Evolve in the Future?

Article Outline

- Technical overview and working principles

- Detailed product specifications and material parameters

- Industry applications and installation logic

- Common questions and professional answers

- Future development and brand perspective

1. How Does a Copper Compression T Fitting Work?

A Copper Compression T Fitting is designed to connect three sections of copper tubing at a 90-degree branching angle without the need for soldering or welding. The fitting operates on a mechanical compression principle, where a compression nut tightens over a compression ring (also known as a ferrule), forcing the ring to deform slightly around the copper pipe. This deformation creates a strong, pressure-resistant seal between the pipe and the fitting body.

Unlike permanent joining methods, compression technology allows controlled mechanical sealing. The copper material plays a crucial role in this process, as its ductility enables uniform compression without cracking. The T-shaped body distributes flow evenly across the branch line while maintaining structural stability under both static and dynamic pressure conditions.

From a system engineering perspective, the effectiveness of a Copper Compression T Fitting depends on dimensional accuracy, surface finish, and torque balance. Proper alignment ensures that compression forces are evenly applied, minimizing the risk of micro-leakage over extended operational cycles.

2. How Are Product Parameters Defined for Copper Compression T Fittings?

Professional evaluation of Copper Compression T Fittings begins with clearly defined technical parameters. These parameters determine compatibility with piping systems, pressure ratings, and compliance with regional standards.

| Parameter | Specification Range | Technical Significance |

|---|---|---|

| Material Grade | C12200 / CW024A Copper | Ensures corrosion resistance and compression flexibility |

| Nominal Sizes | 6mm – 54mm / 1/4” – 2” | Supports residential and commercial pipe diameters |

| Pressure Rating | Up to 25 bar (depending on size) | Defines maximum safe operating pressure |

| Temperature Range | -20°C to 120°C | Suitable for hot and cold water systems |

| Thread Standard | ISO / ASME Compatible | Ensures cross-market installation compatibility |

These parameters collectively determine installation safety and service life. In professional procurement scenarios, tolerance control and certification documentation are often as critical as the physical dimensions themselves.

3. How Is a Copper Compression T Fitting Applied Across Industries?

Copper Compression T Fittings are extensively used in residential plumbing, commercial buildings, HVAC circulation lines, refrigeration systems, and light industrial fluid transport. Their ability to provide secure branching connections without heat makes them particularly valuable in environments where open flames are restricted.

In renovation projects, compression fittings reduce downtime by eliminating curing or cooling periods associated with soldering. In commercial facilities, standardized compression fittings support modular system design, enabling faster maintenance and line reconfiguration.

From a compliance standpoint, copper fittings align with drinking water safety requirements in many regions due to copper’s antimicrobial properties and material stability. This makes Copper Compression T Fittings a long-term solution for potable water distribution.

Common Questions About Copper Compression T Fittings

Q: How tight should a Copper Compression T Fitting be installed?

A: Installation torque should be sufficient to compress the ferrule evenly without deforming the fitting body. Typically, hand-tightening followed by a controlled wrench turn ensures optimal sealing while preventing thread damage.

Q: How long can a Copper Compression T Fitting last in service?

A: When installed correctly and used within rated pressure and temperature limits, a Copper Compression T Fitting can perform reliably for decades, matching the service life of copper piping systems.

Q: How does a Copper Compression T Fitting compare to soldered joints?

A: Compression fittings provide immediate sealing without heat and allow disassembly, whereas soldered joints offer permanent connections. Selection depends on maintenance strategy, installation environment, and regulatory requirements.

4. How Will Copper Compression T Fittings Evolve in the Future?

Future development of Copper Compression T Fittings is driven by increasing demand for standardized, tool-efficient installations and sustainable materials. Precision machining, improved surface treatments, and enhanced quality control are shaping next-generation compression fittings.

Digital construction workflows and prefabricated piping assemblies are also influencing fitting design. Compression fittings that support faster alignment verification and consistent torque application are becoming more prevalent in large-scale projects.

Within this evolving landscape, Gangxin continues to focus on material consistency, dimensional accuracy, and compliance with international standards. By aligning manufacturing processes with real-world installation needs, Gangxin positions its Copper Compression T Fittings to meet long-term infrastructure demands.

For system designers, contractors, and distributors seeking dependable copper fitting solutions, professional consultation ensures optimal product selection and application alignment. Contact us to discuss specifications, bulk supply options, and technical support related to Copper Compression T Fittings engineered for demanding environments.